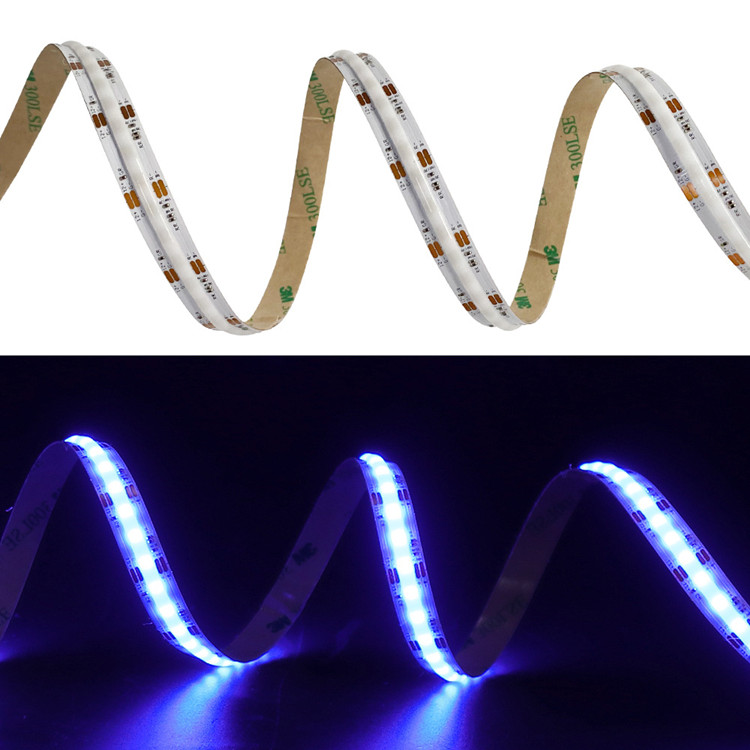

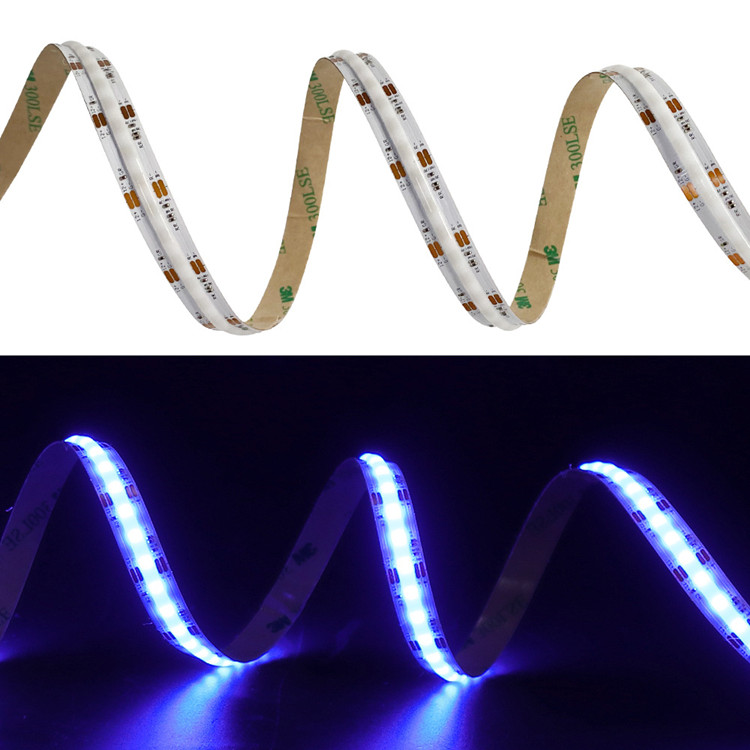

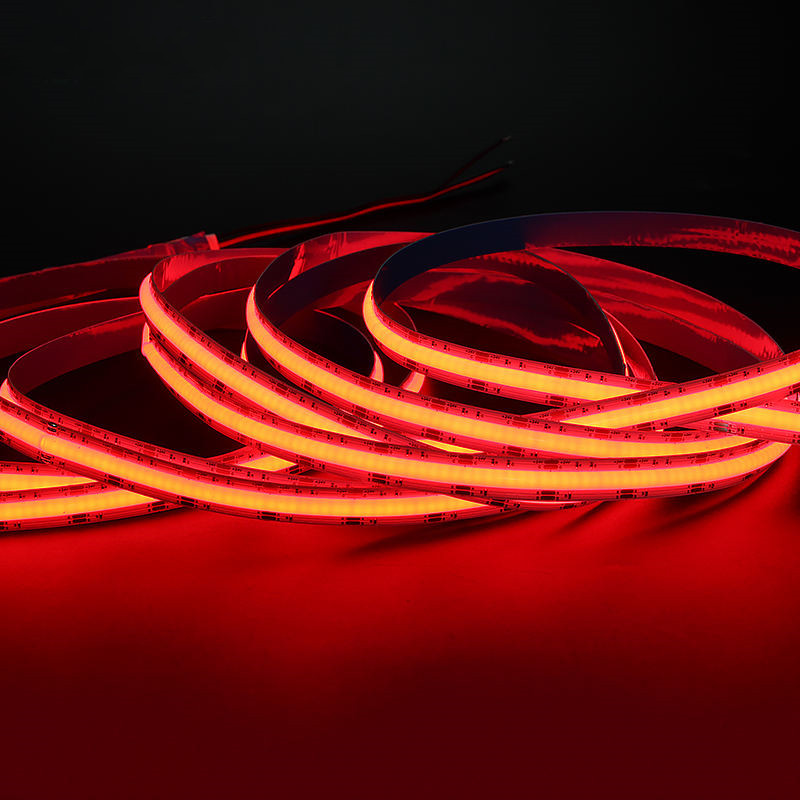

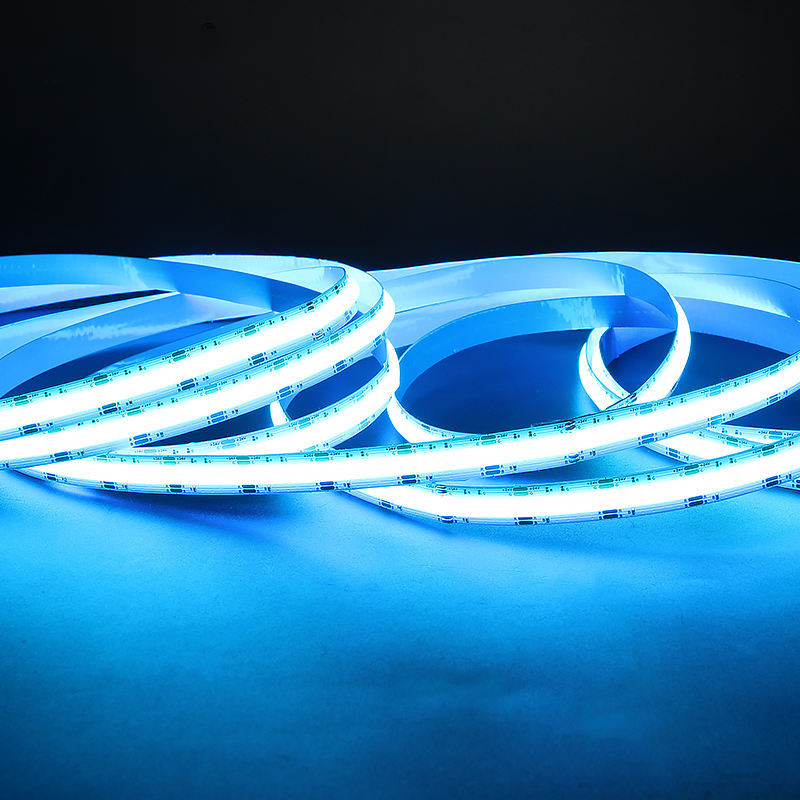

RGB COB LED strip series:

|

|

|

|

| ES-RGBCOB-12-756 |

ES-RGBCOB-24-768 |

ES-RGBCOB-12-810 |

ES-RGBCOB-24-840 |

|

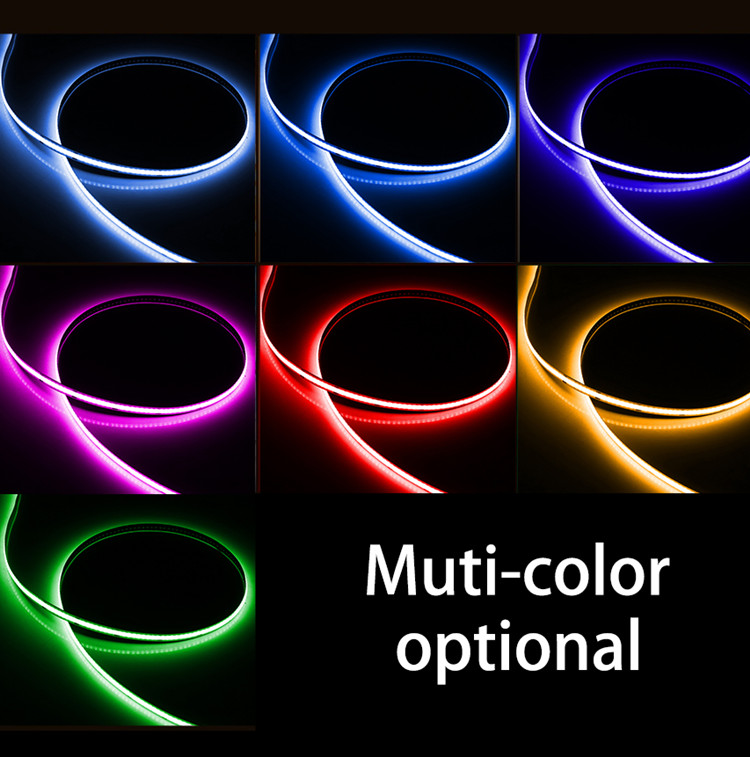

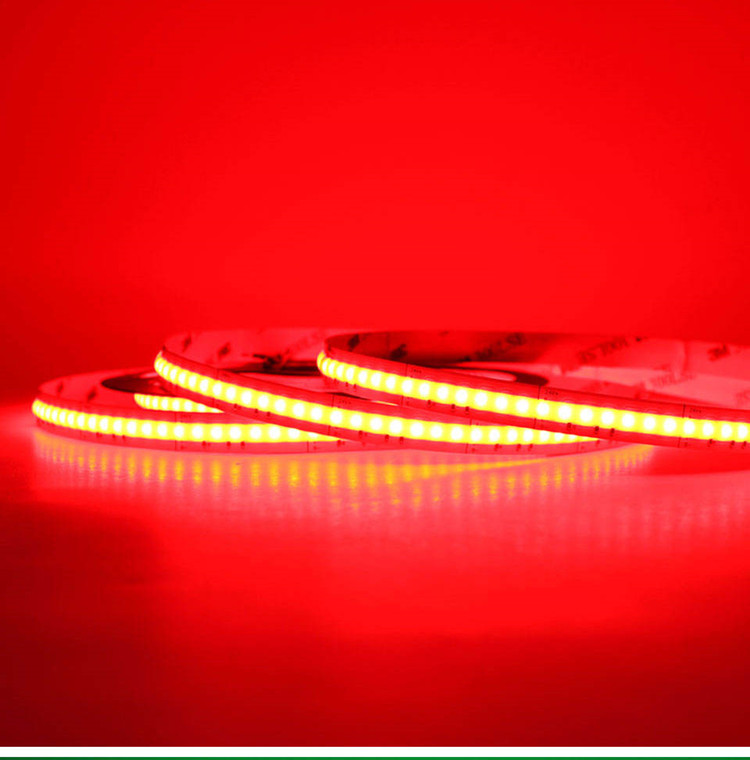

Color: RGB |

|||

| 756leds/M | 768LEDs/M |

810LEDs/M |

840LEDs/M |

| Power:14.4w/M | Power:14.4W/M | Power: 15W/M | Power:15W/M |

| Current:1.2A/M | Current:0.6A/M | Current:1.25A/M | Current:0.625A/M |

|

PCB Width: 10MM |

|||

|

IP:IP20 non waterproof/IP67Casing waterproof/IP68 Gule Waterproof |

|||

|

Beam angle:180° |

|||

|

Operating Temperature:-20°-45° |

|||

|

Storage Temperature:-30°-65° |

|||

|

Package:5M/Roll,10M/RollOr customized length |

|||

| Warranty:2-3 years | |||

The production process of COB led strip products of Easton Technology Co., Ltd. is:

1.) First coat the PCB pads with solder paste through an automatic solder paste machine. The coating uniformity and thickness of the solder paste determine the quality and flatness of the soldered chips, as well as the quality of the soldered chips; Apply solder paste

2.) Load the PCB board coated with solder paste on the carrier, input and set the die-bonding program of the chip through computer programming, adjust the direction and height of the die-bonding, and confirm the electrode direction of the chip;

3.) Do a small-batch die-bonding test first, and inspect the appearance quality of the solid-bonded PCB to determine the direction of the die-bonding, whether there is solder paste connected, and whether the position of the die-bonding is correct, and the inspected product will flow into the next process. ;

4.) Put the solid crystal PCB board and wafer into reflow soldering, set the temperature and speed of reflow soldering, solder the LED chip firmly in the reflow soldering, and conduct an electrical test after being released to test whether the LED chip emits normally. ;

5.) After testing the LED chip on the PCB board, carry out the powder mixing process of silica gel and phosphor powder, according to the photoelectric parameters such as color temperature and brightness specified by the customer, carry out different proportions of configuration, and carry out positive air defoaming of the prepared glue

6.) Fix the PCB board on the glue dispenser carrier for the glue dispensing process. The glue dispensing process is the most critical process for the success of the light strip. After dispensing, put the PCB board into the oven for baking. The glue from different manufacturers If the baking conditions are inconsistent, you must refer to the manufacturer's requirements for verification before setting the appropriate baking temperature.

7.) After the glue is dispensed, test the photoelectric parameters of the light strip to see if the test data meets the customer's requirements.

8.) After welding the 0.5-meter PCB board, connect it to the requirements ranging from 5-10 meters;

9.) Aging detection

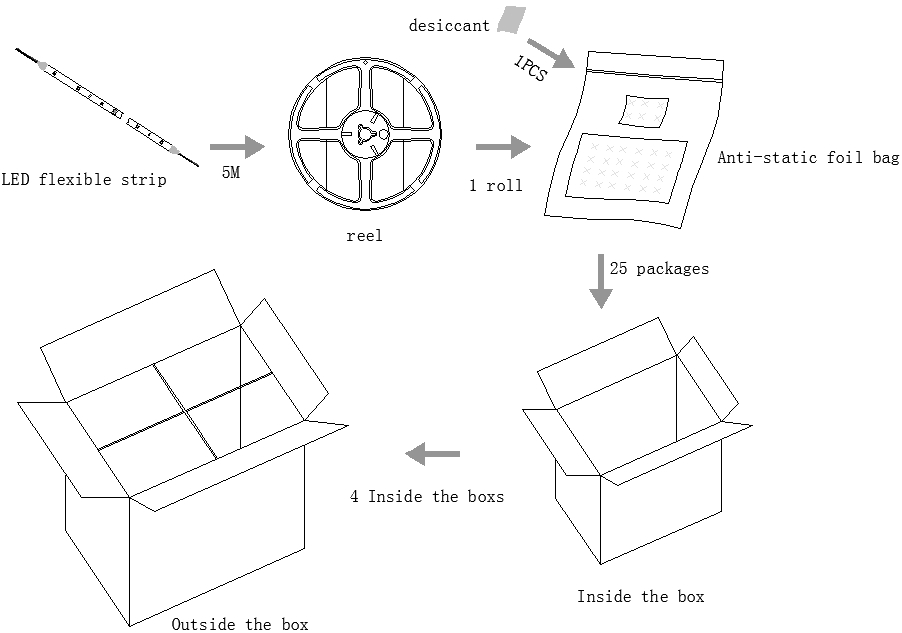

10.) Pack the light strip with a reel after testing the adhesive;

11.) Check again after the reel, put it in an electrostatic bag, and pack it into a box

The differences between COB led strip products and SMT LED strip products of Easton Technology Co., Ltd. are as follows:

|

characteristic type |

COB LED strip | SMD LED strip | |

|

similarity |

Elongated,LED light source, flexible PCB, can be cut and spliced |

||

|

differentia |

Craftsmanship |

cob: is the English abbreviation of Chip on Board, which means on-board chip packaging technology. COB light strips are light strips that encapsulate chips on flexible boards. At present, most of the chips use flip-chip flip-chips, which are firmly arranged in a linear manner. It is bonded on the flexible PCB, and then the colloid is directly wrapped on the surface of the chip |

SMD refers to surface mount components. Usually, the SMD light strip we say is to attach a number of independent lamp beads (2216/2110/2835/3528/5730/5050/3014, etc.) to the PCB board. |

| glow effect | Due to the continuity of the fluorescent glue coating and the small spacing between the chips, the cob light strip emits a line with soft light, which realizes the feature of seeing the light but not seeing the light. | SMD is composed of a single LED lamp bead, the distance between the lamp beads is large, and the light spot can be seen after lighting | |

| heat dissipation | The COB light strip is flip-chip directly packaged on the flexible circuit board, the heat is directly transferred to the circuit board, the heat dissipation efficiency is higher, and the light decay is smaller | The SMD light strip uses the chip packaged in the LED bracket shell, and the heat dissipation needs to be transmitted to the circuit board through the bracket, and the heat dissipation path is relatively complicated | |

Easton Technology Co., Ltd.'s RGB COB led light strip products are widely used in holiday light shows, clothing, game consoles, gaming machines, e-sports equipment, computer cases, TV backgrounds, clothing, automotive, architectural lighting, sign lighting, cabinet and shelf lighting , backlighting and related occasions such as stage, home theater, wine cellar, yacht and cruise ship, etc.

Packing:

Contact: luis lee

Phone: 13049850031

Tel: 13554982239

Email: sales@oureaston.com

Add: Shangpai Industrial Zone,Shiyan Town, Baoan District, Shenzhen