| Picture |

|

|

| Model | ES-WS2811-COB-630 | |

|

Input voltage |

12V | 24V |

| Power | 16W | |

| LED QTY |

630leds/m |

|

| Color |

RGB |

|

| pcb width |

12mm |

|

| pcb color | 白色 | |

| chip | 三安/晶元 | |

| IC |

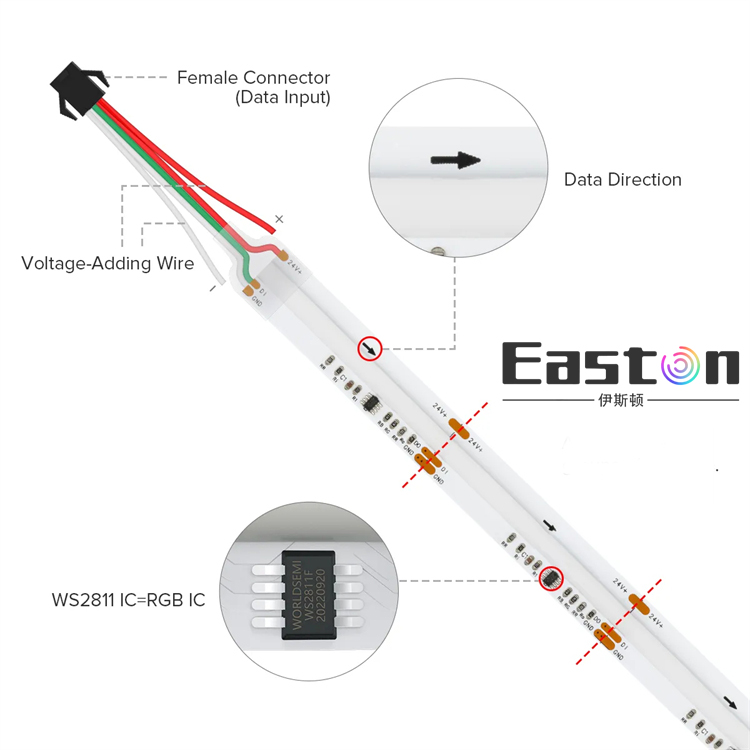

ws2811/ucs1903/sm6703 |

|

| Cutability | 71.42mm | 100mm |

| Install | 3M | |

| IP |

IP20/IP67/IP68 |

|

| Warranty |

2-3年 |

|

| Warranty |

CE ROSH |

|

Product description:

The ws2811 COB product of Easton Technology Co., Ltd. adopts a three-channel controller integrated special circuit, which has MCU digital interface, latch and shaping amplifier circuit inside. Through the return-to-zero code communication method, the transmission distance between any two points can be realized. 20 meters does not require a signal amplification circuit, with 256 gray levels, scanning frequency 2.5Khz, serial interface design, complete data reception and decoding through a signal line, combined with RGB LEDs can achieve 16.7 million different changes Effect

The purpose of the ws2811 COB product of Easton Technology Co., Ltd. is to add dreamy colors to spaces that require linear light sources. The products are widely used in festival light shows, clothing, game consoles, gaming machines, e-sports equipment, computer cases, and TV backgrounds , clothing, automotive, architectural lighting, logo lighting, cabinet and shelf lighting, and decorative lighting for stages, home theaters, wine cellars, cars, bicycles, yachts and cruise ships, etc.

The ws2811 COB products of Easton Technology Co., Ltd. can realize different functions through mini three-button controllers, RF controllers, Bluetooth controllers, music controllers, programmable controllers, online controllers, DMX consoles, Madix, Aduino, etc. Effect: static, static change, running water chase, colorful change, colorful chase, animation, etc.

The ws2811 COB product of Easton Technology Co., Ltd. can choose two specifications of 12V or 24V power supply. The quality of the product is controlled through multiple processes to ensure the quality. Compared with other products, the light effect is more uniform and soft

The production process of Easton Technology Co., Ltd.'s COB led light strip products is:

1.) First apply the solder paste to the PCB pad through an automatic solder paste brushing machine. The uniformity and thickness of the solder paste determine the quality and flatness of the soldered chip, as well as the quality of the soldered chip; so uniform Apply solder paste

2.) Load the PCB board coated with solder paste on the carrier, input and set the die-bonding program of the chip through computer programming, debug the direction and height of the die-bonding, and confirm the electrode direction of the chip;

3.) Do a small batch of die-bonding test first, inspect the appearance quality of the solid-chip PCB, determine the direction of the die-bonding, whether there is solder paste, whether the position of the die-bonding is correct, and then flow the inspected products into the next process ;

4.) Put the solid crystal PCB board and chip into the reflow soldering, set the temperature and speed of the reflow soldering, solder the LED chip firmly in the reflow soldering, and conduct an electrical test after it comes out of the oven to test whether the LED chip is emitting light normally ;

5.) After testing the LED chips on the PCB board, carry out the powder mixing process of silica gel and fluorescent powder, and configure different proportions according to the photoelectric parameters such as color temperature and brightness specified by the customer, and carry out positive air defoaming of the prepared glue

6.) Fix the PCB board on the dispensing machine carrier for the dispensing process. The dispensing process is the most critical process for the success of the light strip. After dispensing, put the PCB board into the oven for baking. Glue from different manufacturers The baking conditions are inconsistent, and the appropriate baking temperature must be set after verification according to the manufacturer's requirements

7.) Test the photoelectric parameters of the light strip after dispensing and baking to see if the test data meets the customer's requirements

8.) After soldering the 0.5-meter PCB board, connect it into requirements ranging from 5-10 meters;

9.) Aging detection

10.) After testing the back glue, pack the light strip with a reel;

11.) Check again after the reel, put it into an electrostatic bag, and pack it into a box

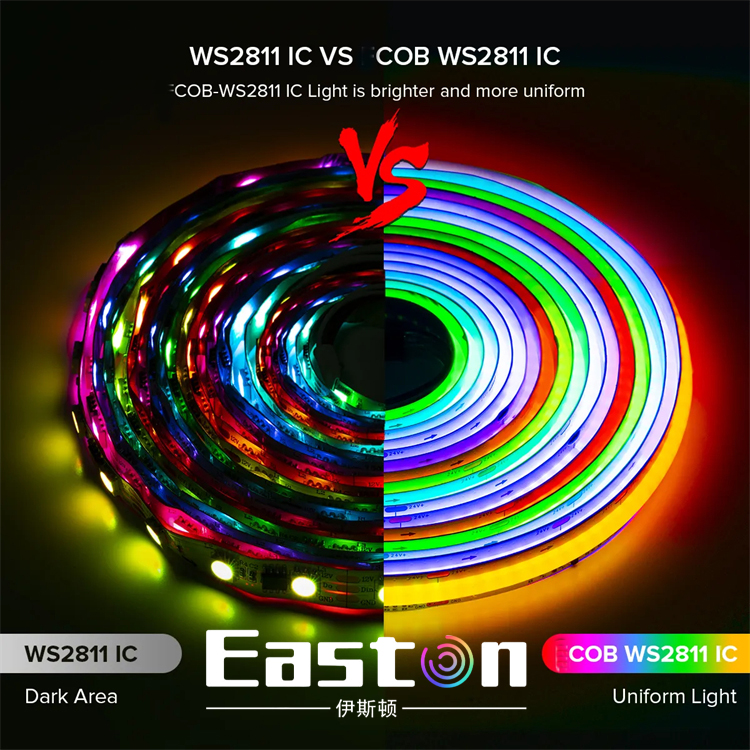

The difference between COB led light strip products and SMT LED light strip products of Easton Technology Co., Ltd. is as follows:

|

characteristic type |

COB LED strip | SMD LED strip | |

|

similarity |

Elongated,LED light source, flexible PCB, can be cut and spliced |

||

|

differentia |

Craftsmanship |

cob: is the English abbreviation of Chip on Board, which means on-board chip packaging technology. COB light strips are light strips that encapsulate chips on flexible boards. At present, most of the chips use flip-chip flip-chips, which are firmly arranged in a linear manner. It is bonded on the flexible PCB, and then the colloid is directly wrapped on the surface of the chip |

SMD refers to surface mount components. Usually, the SMD light strip we say is to attach a number of independent lamp beads (2216/2110/2835/3528/5730/5050/3014, etc.) to the PCB board. |

| glow effect | Due to the continuity of the fluorescent glue coating and the small spacing between the chips, the cob light strip emits a line with soft light, which realizes the feature of seeing the light but not seeing the light. | SMD is composed of a single LED lamp bead, the distance between the lamp beads is large, and the light spot can be seen after lighting | |

| heat dissipation | The COB light strip is flip-chip directly packaged on the flexible circuit board, the heat is directly transferred to the circuit board, the heat dissipation efficiency is higher, and the light decay is smaller | The SMD light strip uses the chip packaged in the LED bracket shell, and the heat dissipation needs to be transmitted to the circuit board through the bracket, and the heat dissipation path is relatively complicated | |

The price is only Led Strip, Not Included Power Supply or Led Controller!Notice:

This product is Led strip only, not including power supply or Led controller!

WS2811 must use DC12V or DC24V power supply and Led controller to control!

Every 0.5 meters with solder joints, please pay attention!

PCB color:

White: white printed circuit board

IP rating:

(1) IP20—not waterproof, indoor use

(2) IP67 - Silicone tubing, resealable after cutting, for outdoor use

(3) IP68 - IP65+IP67, can work underwater (we can customize it for you if necessary!)

Product parameters:

(1) Working voltage: DC 12V/24V

(2) LED chips: Epistar or Sanan

(3) LED Quantity: 630leds/m

(4) Power: 16W/M

(5) Gray scale: 256/color

(6) Lighting angle: 180°

(7) Color mode: 133 patterns and 100 speeds

(8) Dimensions: 5000mm × 12mm × 2.4mm

(9) Packing: 5m/roll 12v ws2811 rgb strip + 3 pin connector

(10) Warranty: 2-3 years

Features:

(1) Flexible PCB (IP20, IP65), with 3M tape on the back, easy to install.

(2) Energy saving and environmental protection.

(3) High brightness COB LED light bar.

(4) Solid state, high resistance to shock or vibration.

(5) Low power consumption and high strength.

(6) The RGB Symphony controller matches the power supply system.

(7) Wide viewing angle.

(8)RGB full color

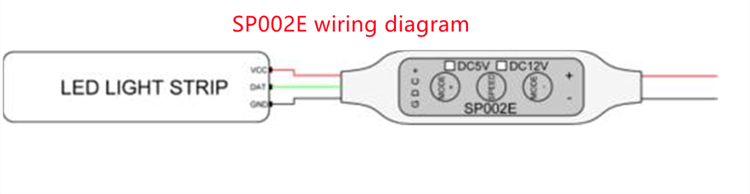

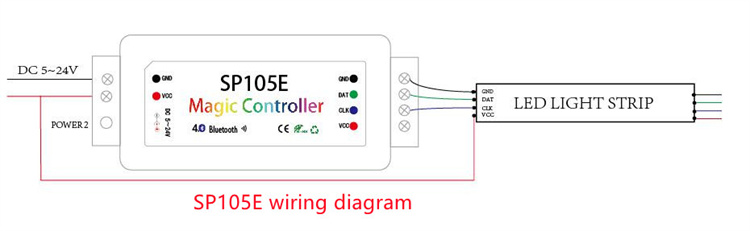

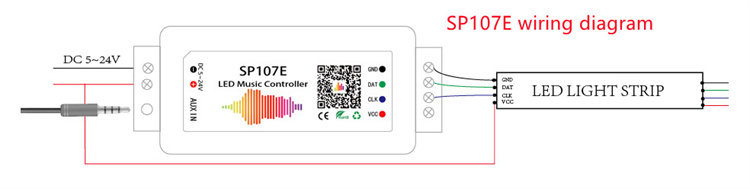

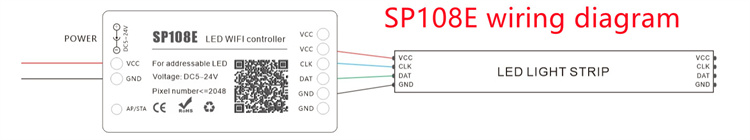

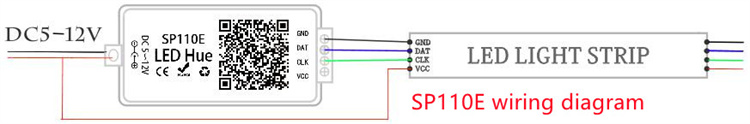

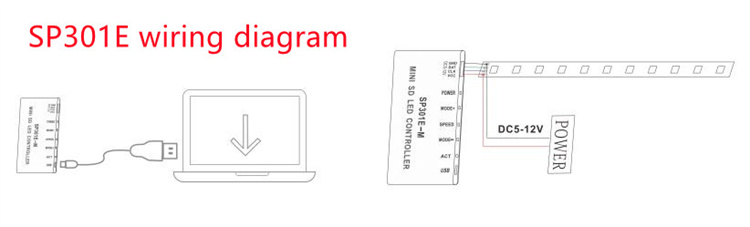

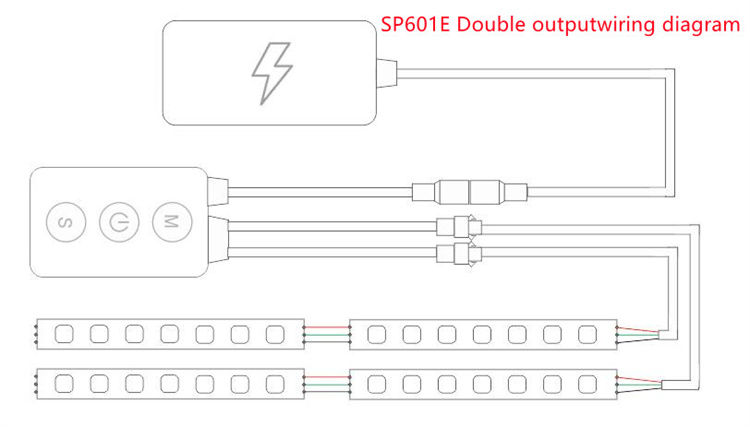

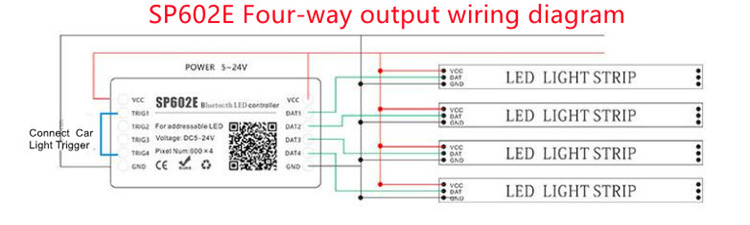

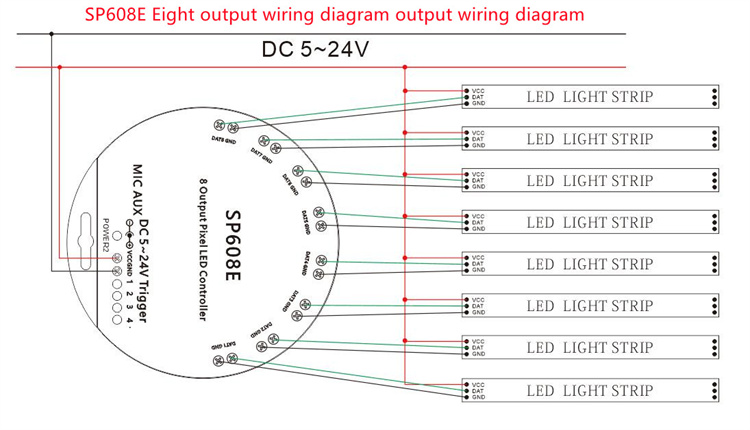

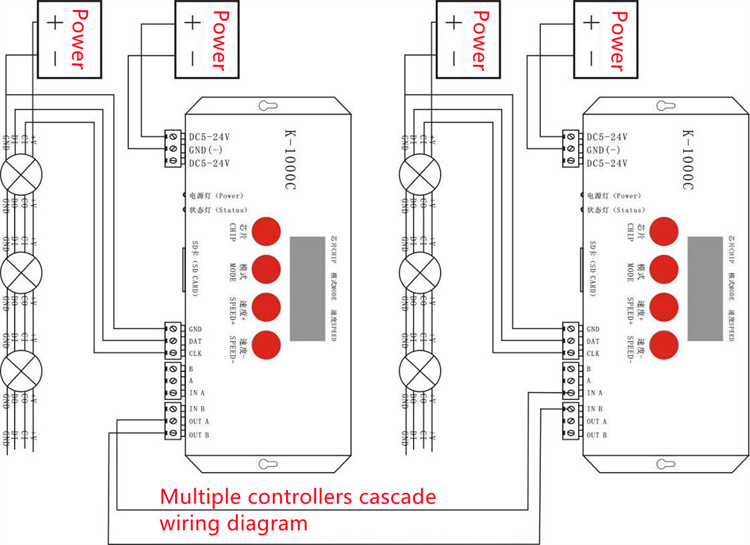

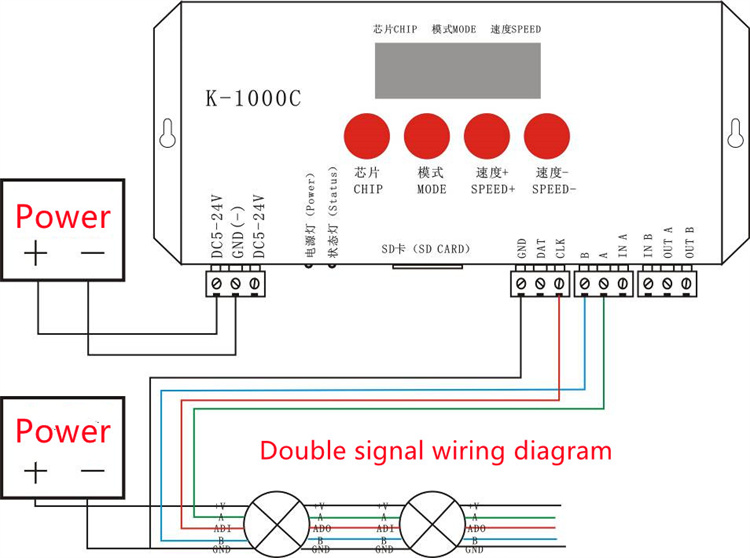

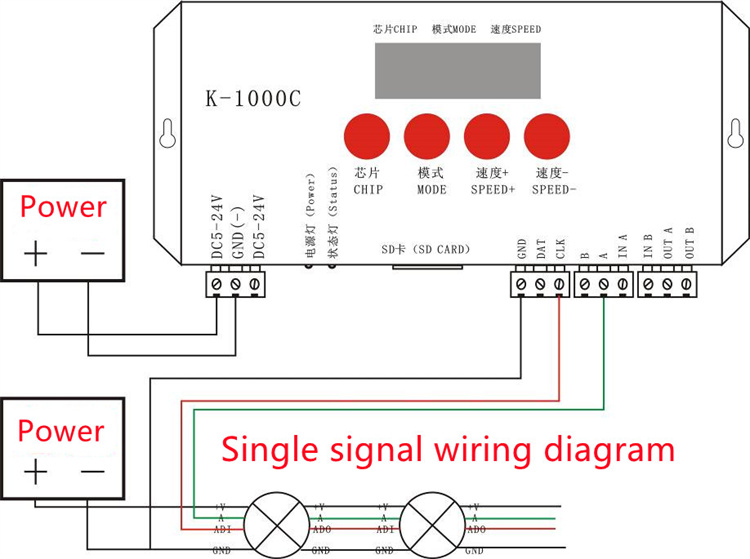

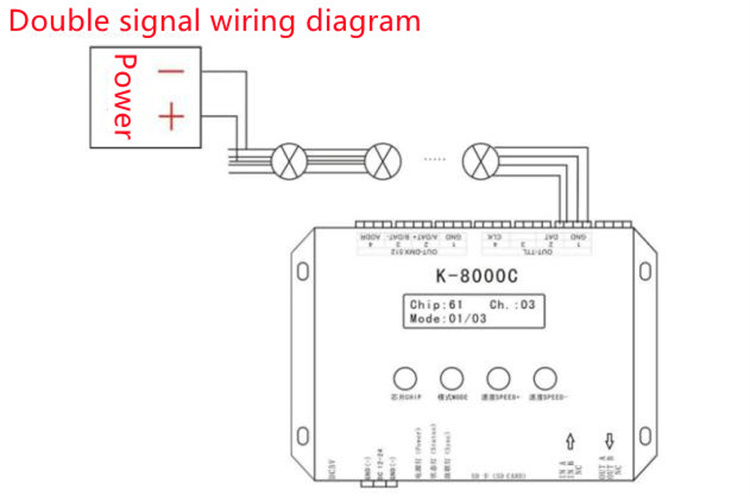

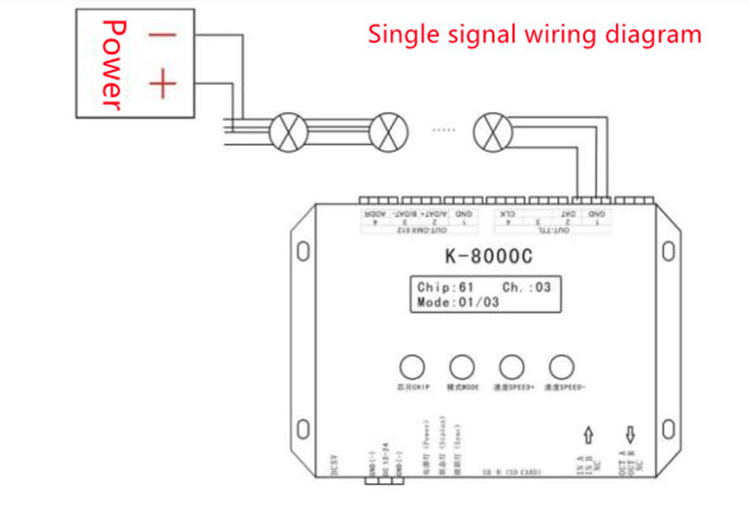

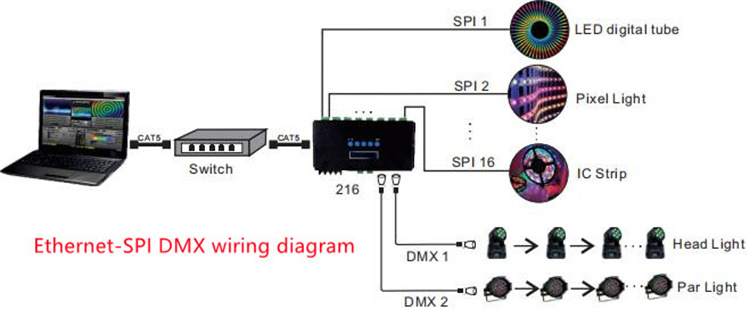

Common controller wiring method:

Contact: luis lee

Phone: 13049850031

Tel: 13554982239

Email: sales@oureaston.com

Add: Shangpai Industrial Zone,Shiyan Town, Baoan District, Shenzhen